Guide for the use of electric motor testing methods based on iec 60034 2 1 p ll determined from residual loss 8 2 2 5 1 in table 2 may 2011 version 1 1 document developed as part of the electric motor systems annex emsa task c testing centres under the iea implementing agreement for a co operating programme on.

Electric motor testing procedure pdf.

Experience is the best teacher in setting up the scheduled periods for your equipment.

Record results on attachment 3 of this procedure.

3 phase motor troubleshooting pdf 3 phase motor winding resistance values 3 phase testing procedure how to test a 3 phase motor with a megger how to test motor windings single phase motor insulation resistance test procedure motor megger test results types of motor testing.

That is with the same test connections and with the same test voltage applied for the same length of time.

To obtain short circuit current and its power factor angle block rotor test is performed on the motor.

3 phase motor testing procedure the patriot mill turn and turnado machines are equipped with 3 phase motors.

Ieee standard test procedure for polyphase induction motors and generators 3 park avenue new york ny 10016 5997 usa ieee power engineering society sponsored by the electric machinery committee 4 november 2004 print.

With the motor at normal operating temperature the vibration velocity shall not exceed 2 8 mm s rms or 4 mm s peak in any direction.

Testing electric motors doesn t have to be a mystery.

Esting and commissioning procedure for motors photo by teco middle east tme the measurements shall be carried out with an instrument conforming to iso 2954 10 1000 hz frequency range.

Similarly the range of ammeter and voltmeter during blocked rotor test 10a 250v.

Ss95211 authorized licensed use limited to.

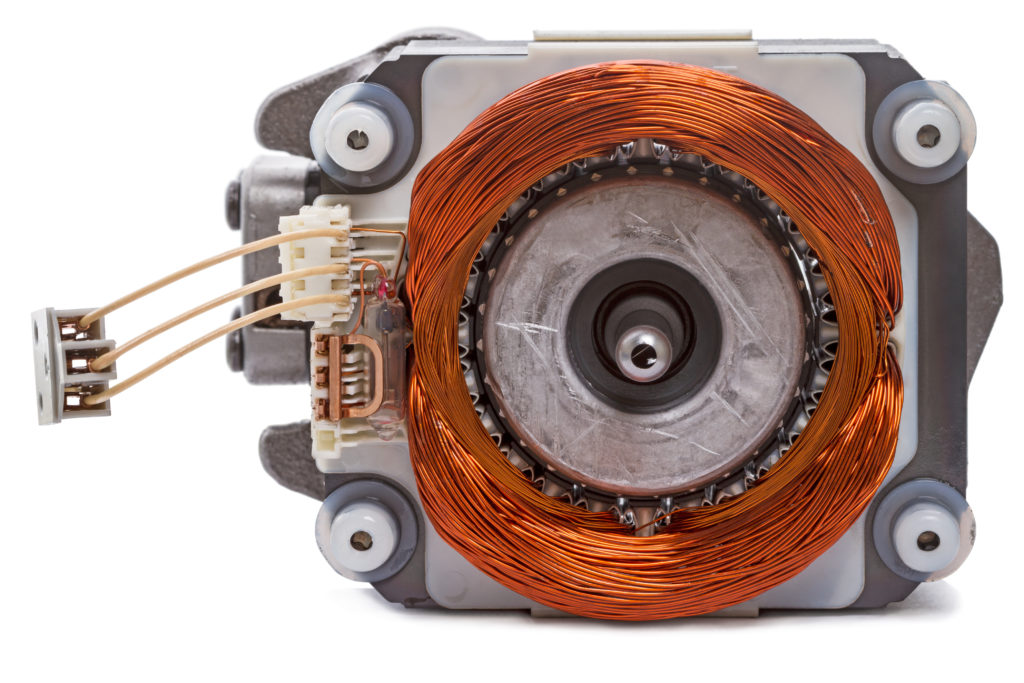

Electric motors have had a reputation for being a mix of science and magic.

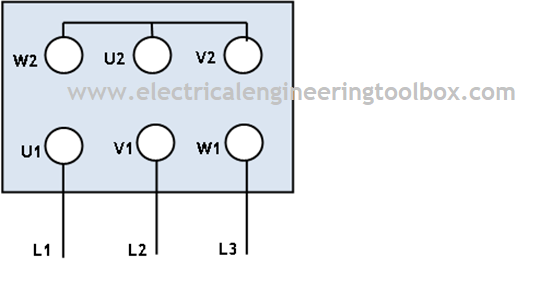

The windings are marked with tags u 1 and u 2 v 1 and v 2 w 1 and w 2.

Each motor has 3 separate windings.

You should make these periodic tests in the same way each time.

So when a motor fails to operate it may not be obvious what the problem is.

For motors 25 hp or greater record motor vibration measurements in accordance with the test equipment manufacturer s instruction manual.

Knowledge of the basics together with powerful new test equipment vastly simplifies the job.

In the running configuration the windings are joined with metal jumpers.

Pump motor or a short control cable may be vital to a process in your plant.